Erosion Protector (Independent Study)

Overview

Over the course of a semester, I designed and iterated a cheap, reproducible product for Duke’s HRL office. AC units on East Campus were dripping condensate in the summer, eroding the side of dormitories and compromising the structural integrity of buildings. The school needed a cheap, nonintrusive solution that could be reproduced 700 times with minimal effort. Additionally, due to mass production, the solution could not be a 3D printed custom design. The final solution features a 1/2” PVC elbow and pipe, L-brackets, one galvanized steel screw, a locknut, and sheet metal screws for attachment. Additionally, a jig was designed to make assembly as fast and easy as possible.

Early Design Process

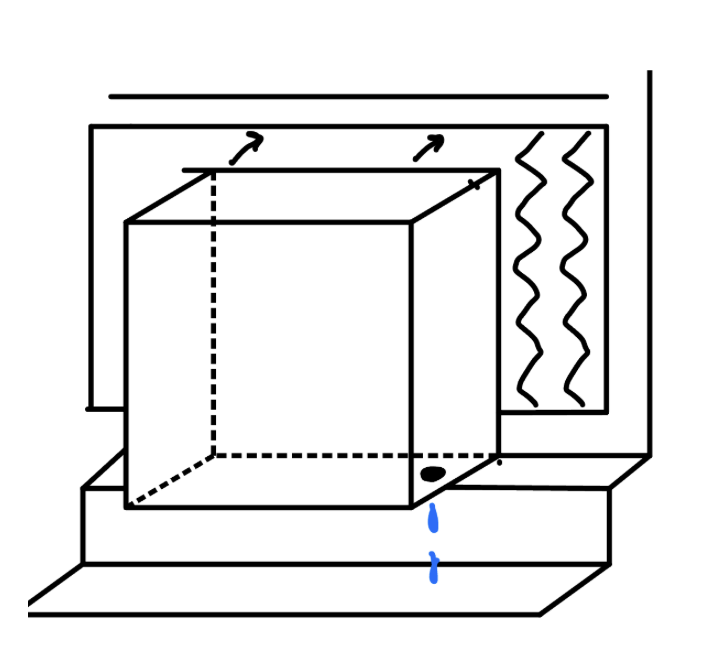

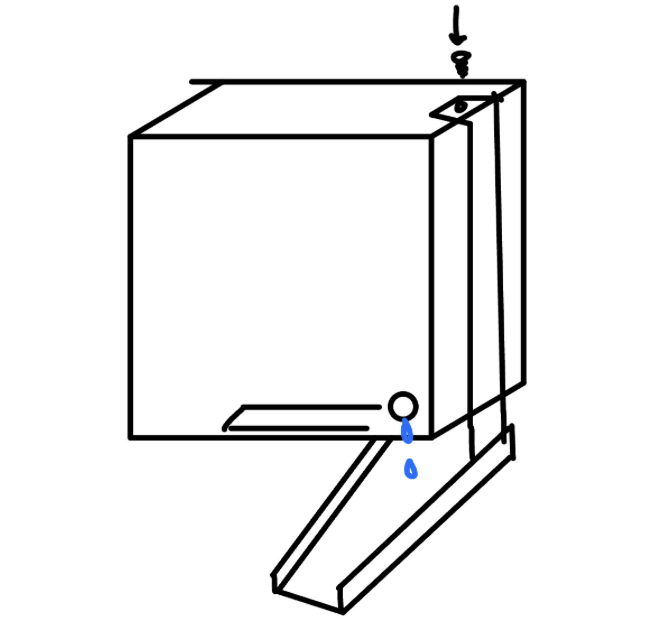

To get a concrete sense of the problem, the team visited the dorms on East Campus and met with HRL. We found that the condensate was dripping out of a hole on the bottom of the unit. We then deconstructed a unit to get a sense of the spacial limitations and machinery inside.

Unit schematic

Early ideas for attachment, including magnet + flange and push-in fitting

Final Design

Assembly and installation

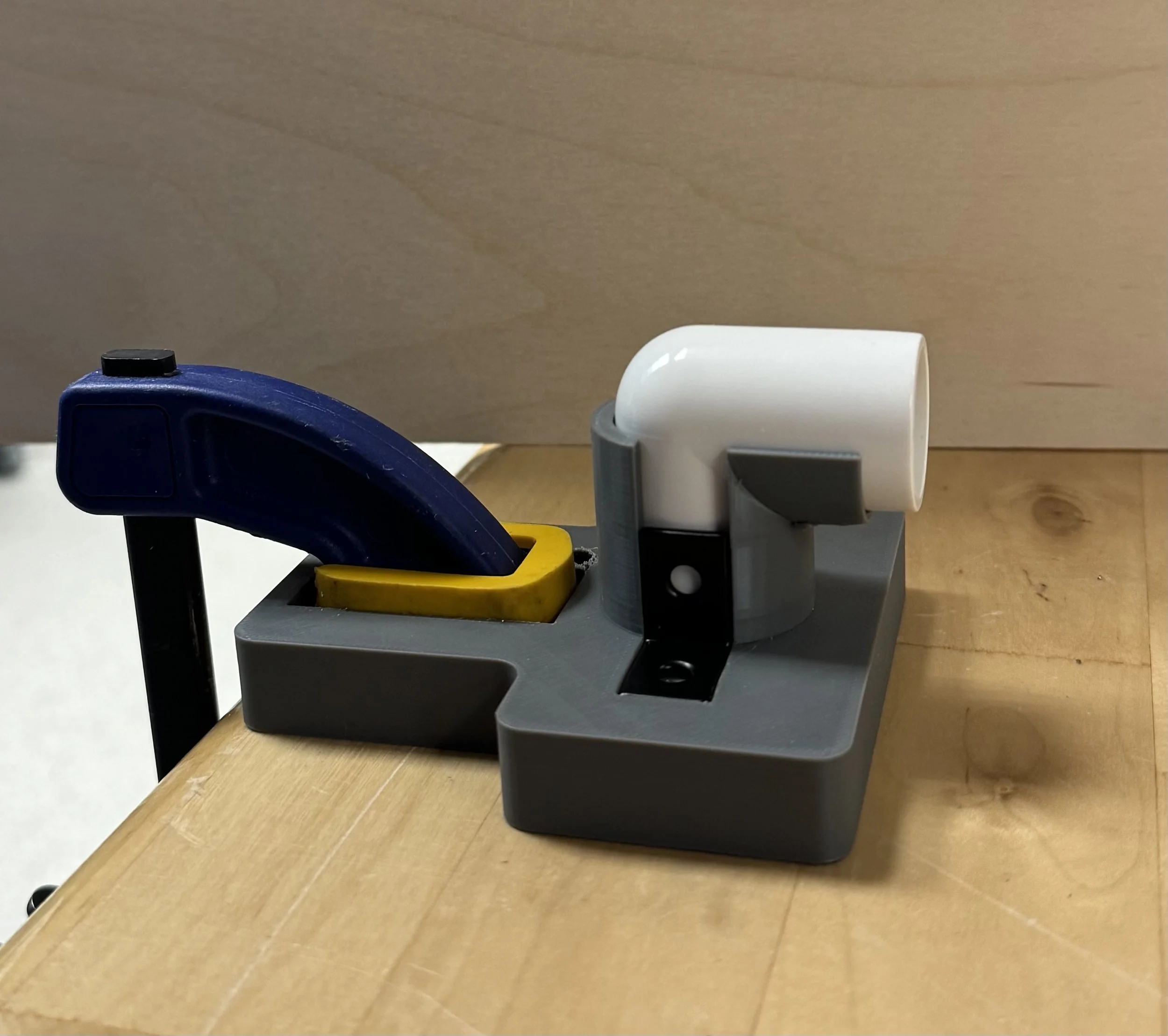

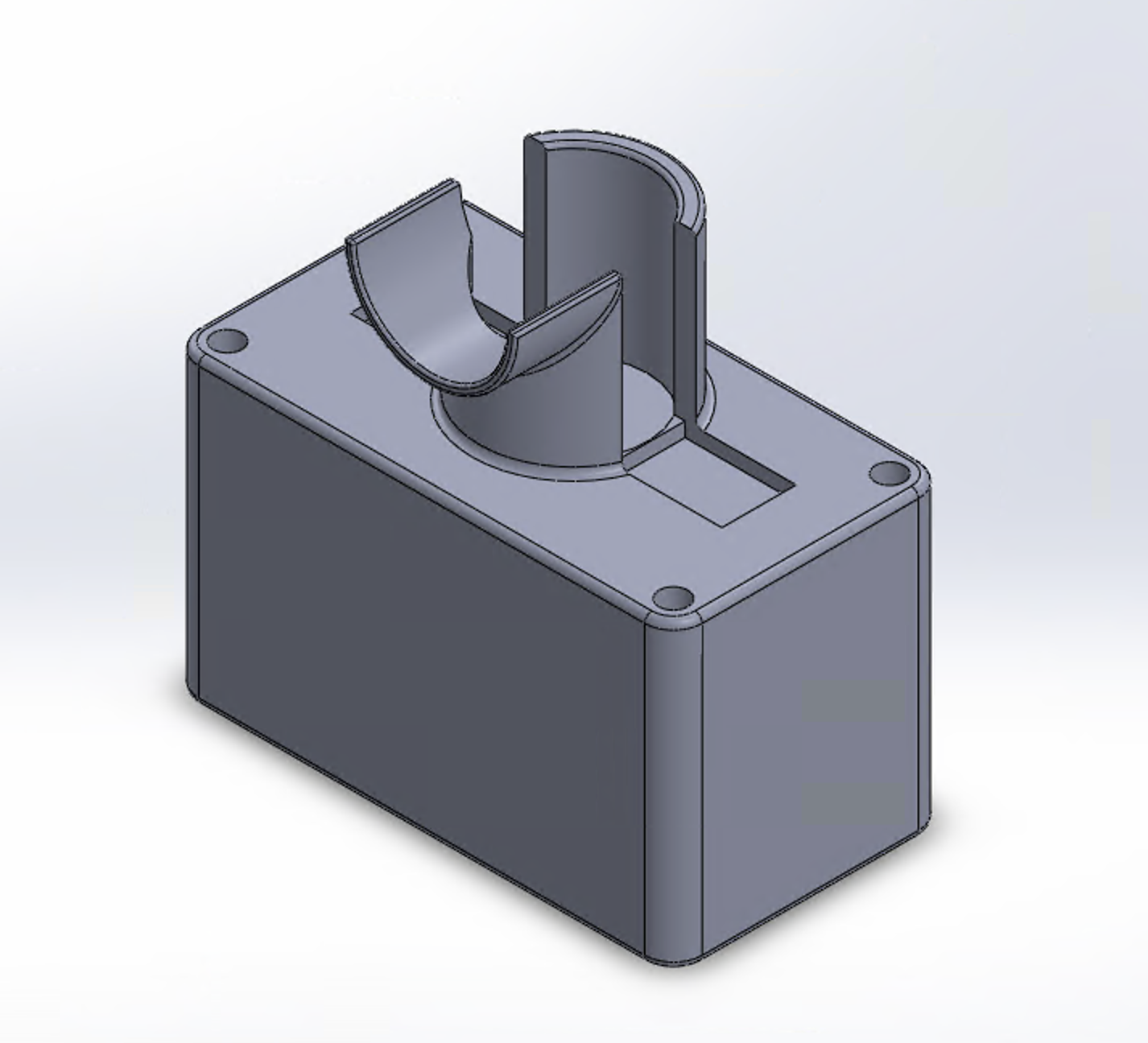

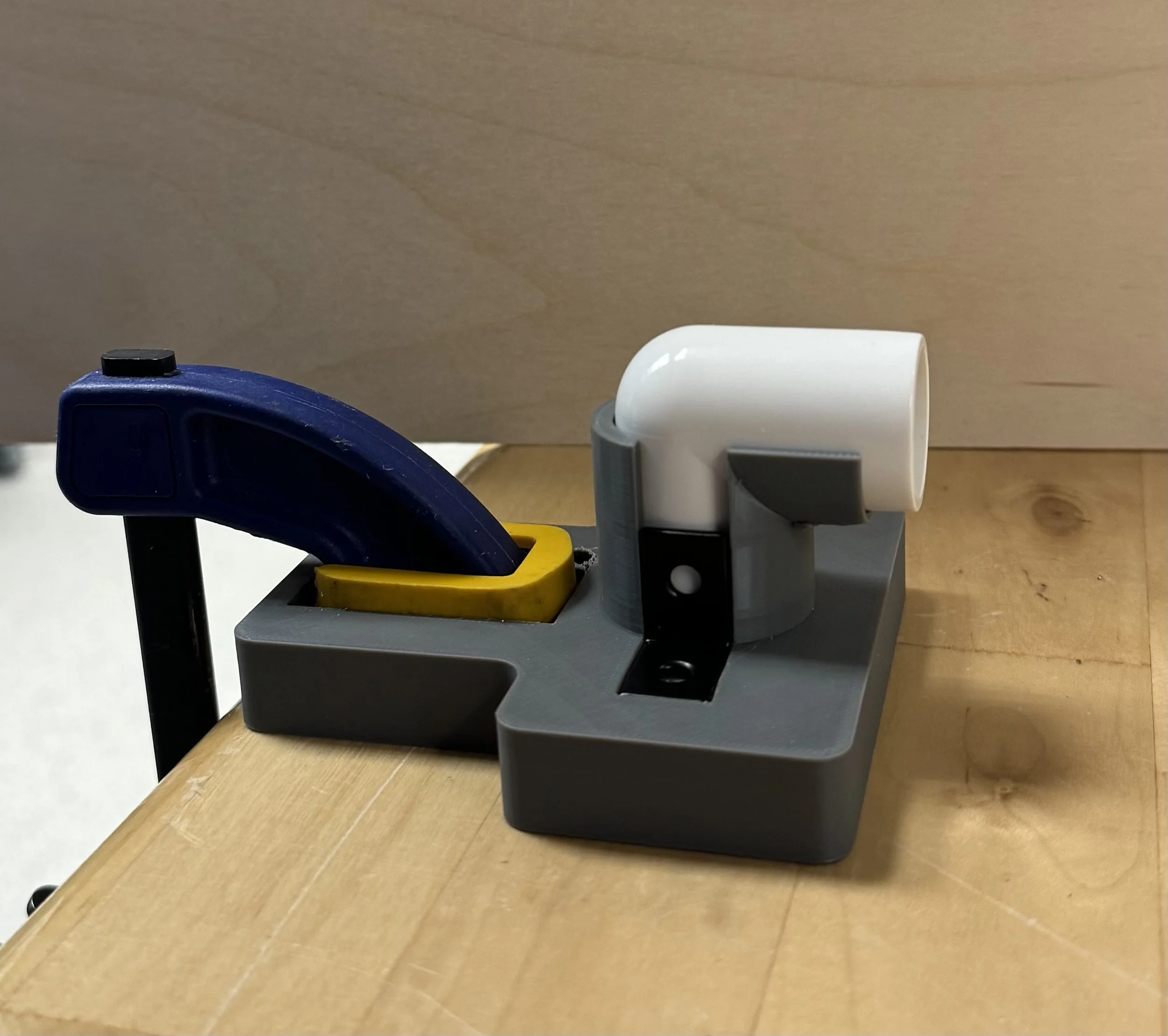

To make assembly more efficient, a jig was designed and iterated for fabrication. This decreased the time of assembly from ~5 min/part to 2 min/part. It also makes assembly more accurate, as the top surface of the L brackets are perfectly flush with the top surface of the PVC elbow. Tolerances are tight for the elbow and L brackets, so that they stay in place while drilling but can be pulled out once assembled. Early iterations were clamped to the table, while the final design features screw holes and will be permanently installed. Additionally, higher clearance for the hand drill was added in the final jig.

Clamped jig and assembly video

Final jig design delivered to HRL

Early cantilever ideation

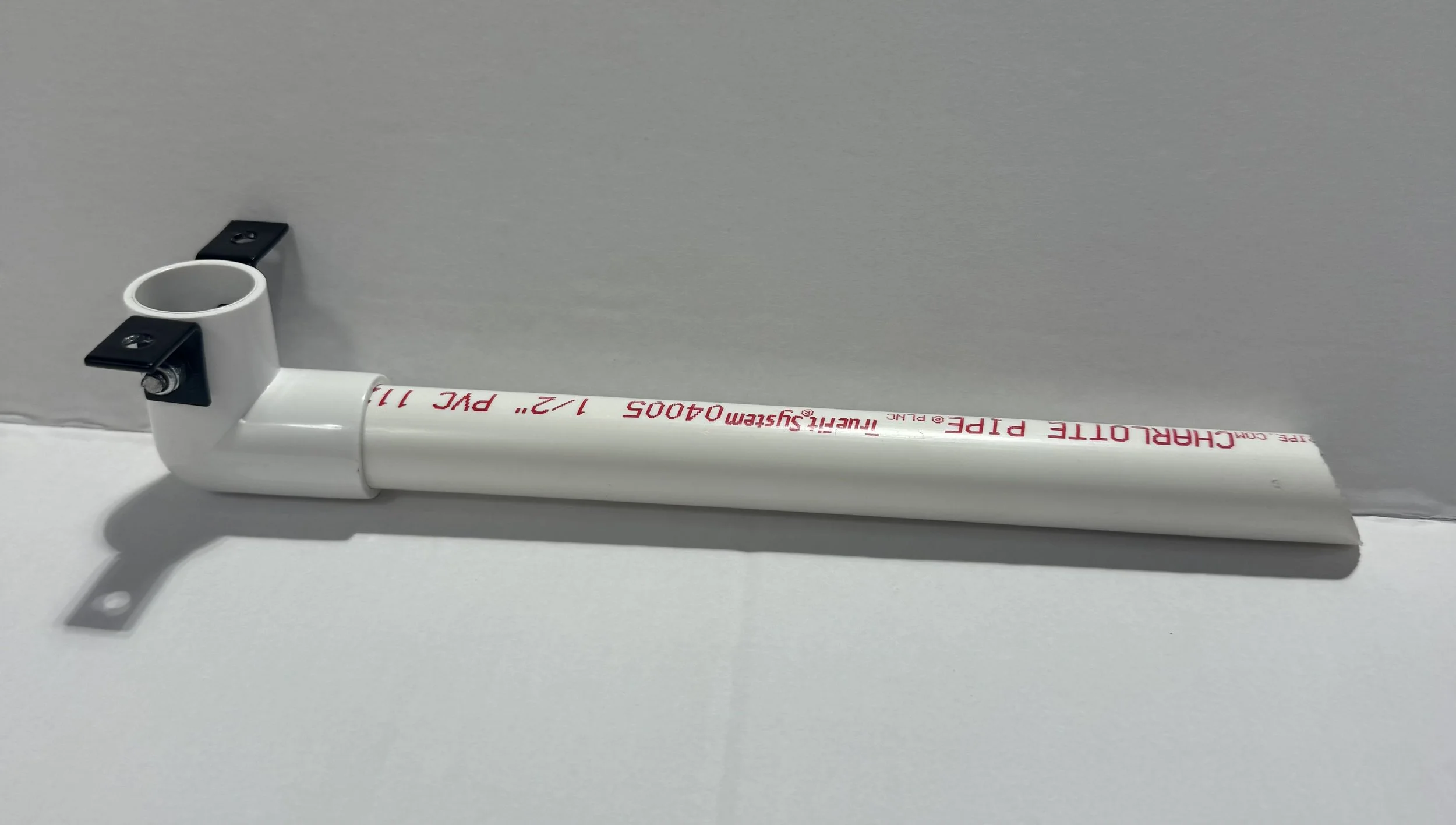

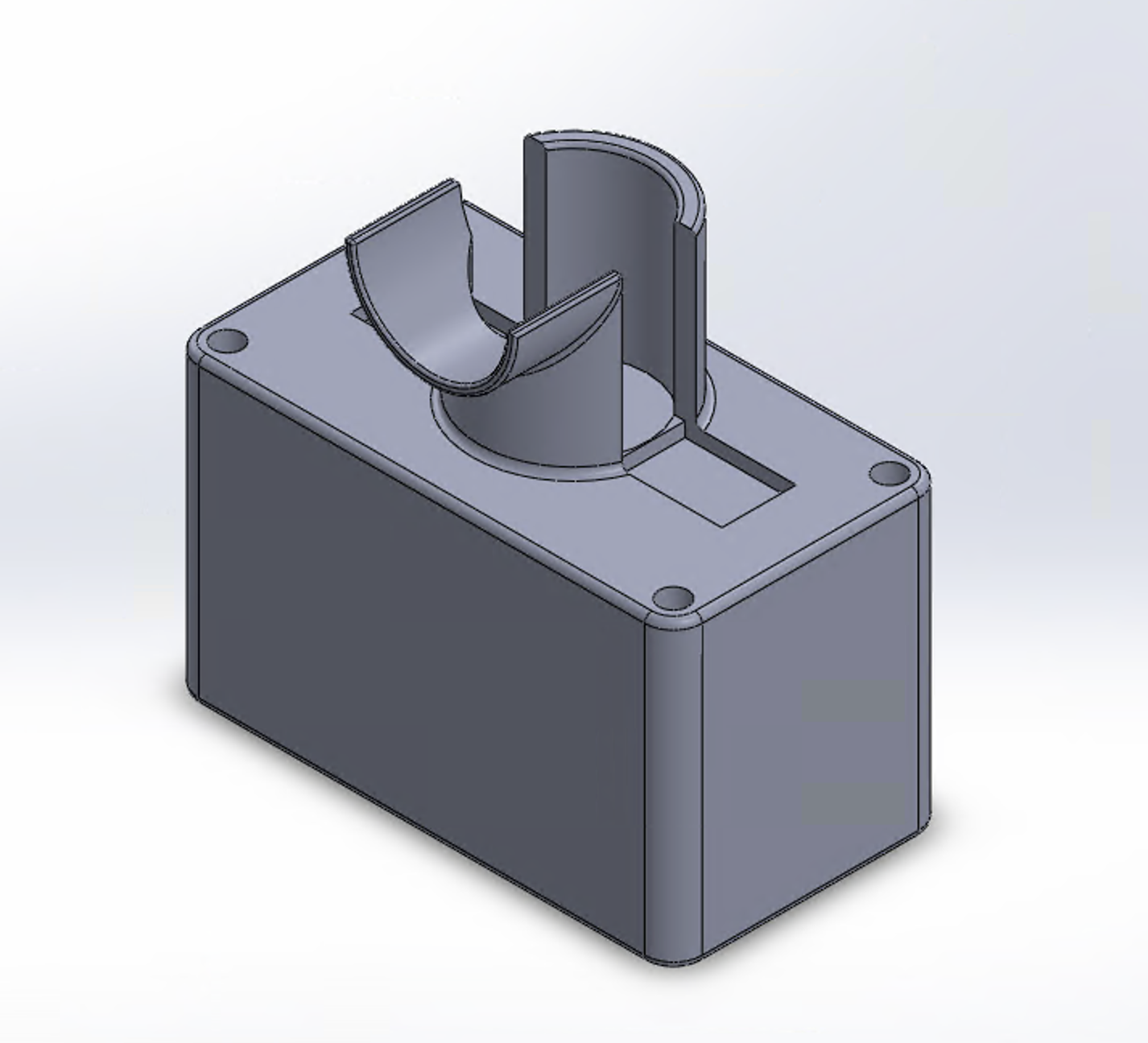

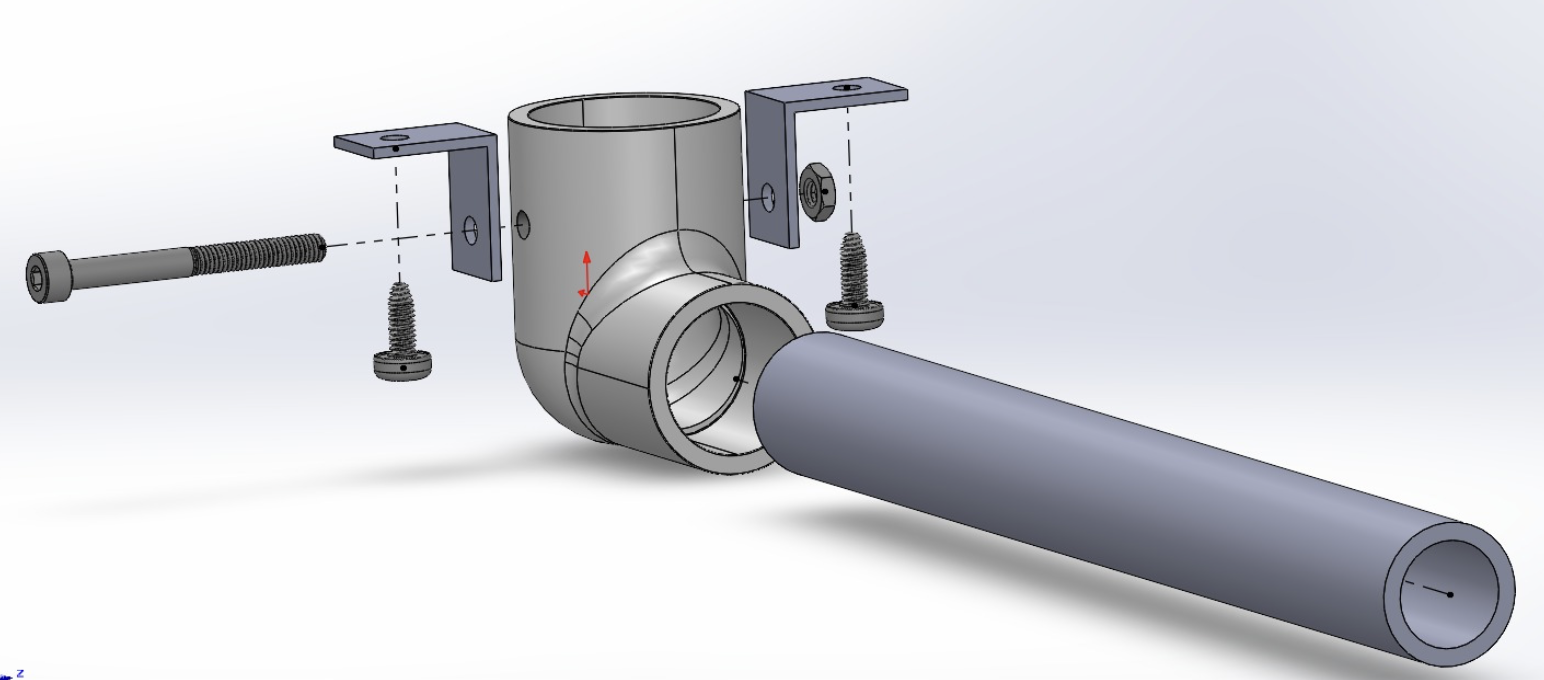

After testing several preliminary 3D printed designs, I designed the final product using 1/2” PVC elbow, 1/2” PVC pipe, two 3/4” L brackets, a 1 1/4” galvanized steel screw, and a locknut. A SolidWorks model and exploded view are shown below.

Material selection

Material selection criteria primarily include weather resistance, weight, cost, and resistance to corrosion (particularly in the screw connecting L brackets). PVC was determined as the optimal material, combining low cost with high lifetime. Additionally, galvanized steel was selected for the screw due to its corrosion resistance. With these materials, the product’s estimated lifetime is 8-10 years without corrosion.

Brainstormed solutions were divided into three categories: attachment, collection, and deflection. Most brainstormed solutions targeted the condensate hole on the bottom surface and featured some sort of cantilever.