Overview

To combat the high barrier to entry of wakeboarding, I designed and fabricated an LED-lined wakeboard that teaches beginners proper weight distribution. The board uses pressure sensors and an IMU sensor to get data on weight distribution and tilt, interprets these signals with an ESP32 microcontroller, and lights up addressable LEDs accordingly. All electronics are fully waterproof and embedded into the board. The microcontroller uses an algorithm developed to model wakeboarding as a multi body dynamic system.

The techniques used in this project include:

Advanced fabrication techniques (threaded fasteners, routing, waterproof sealing, 3D design, custom bracket design)

Finite element analysis, dynamic system modeling, structural and material analysis

Soldering

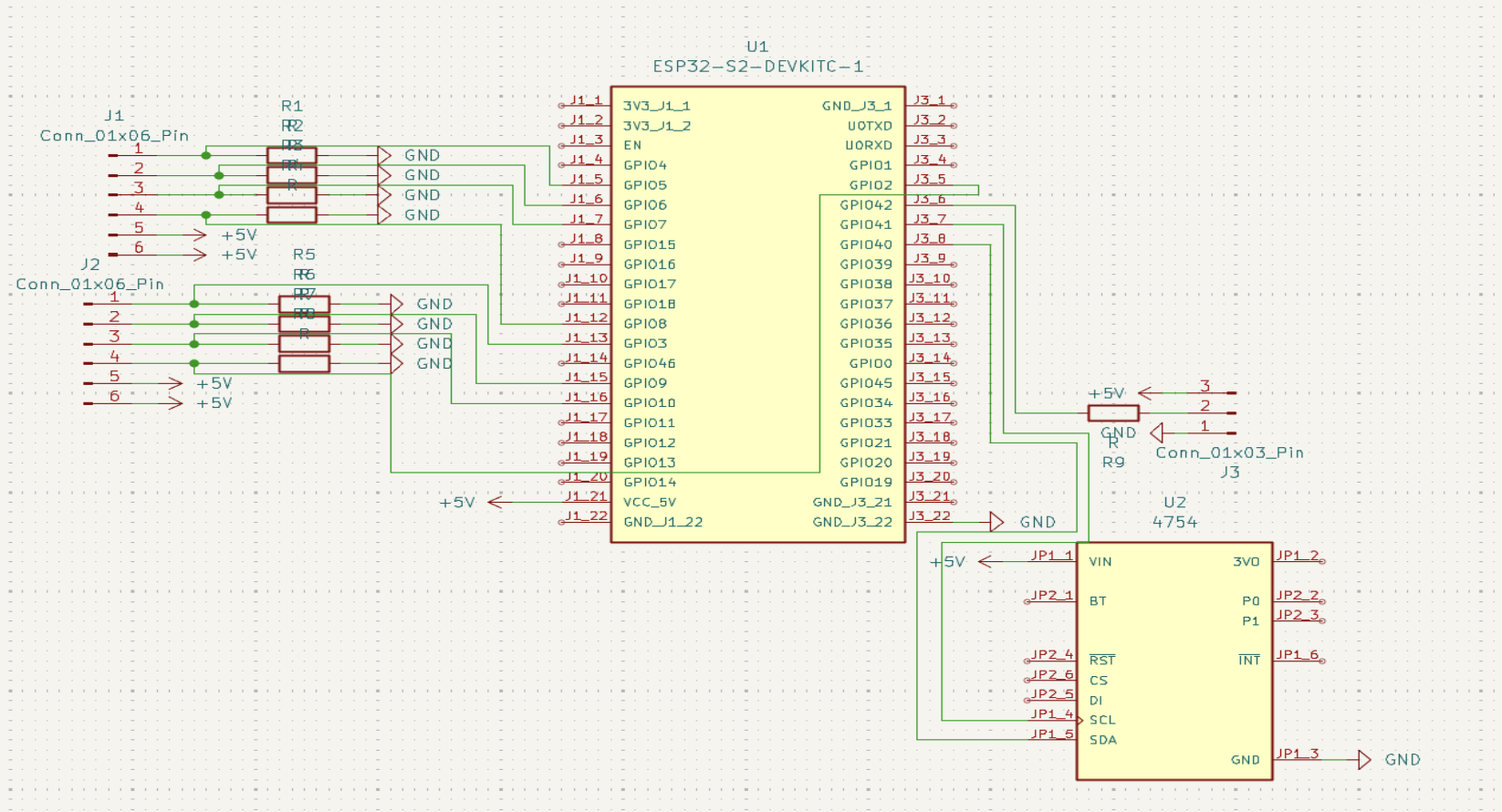

PCB design

Commercial-focused product design

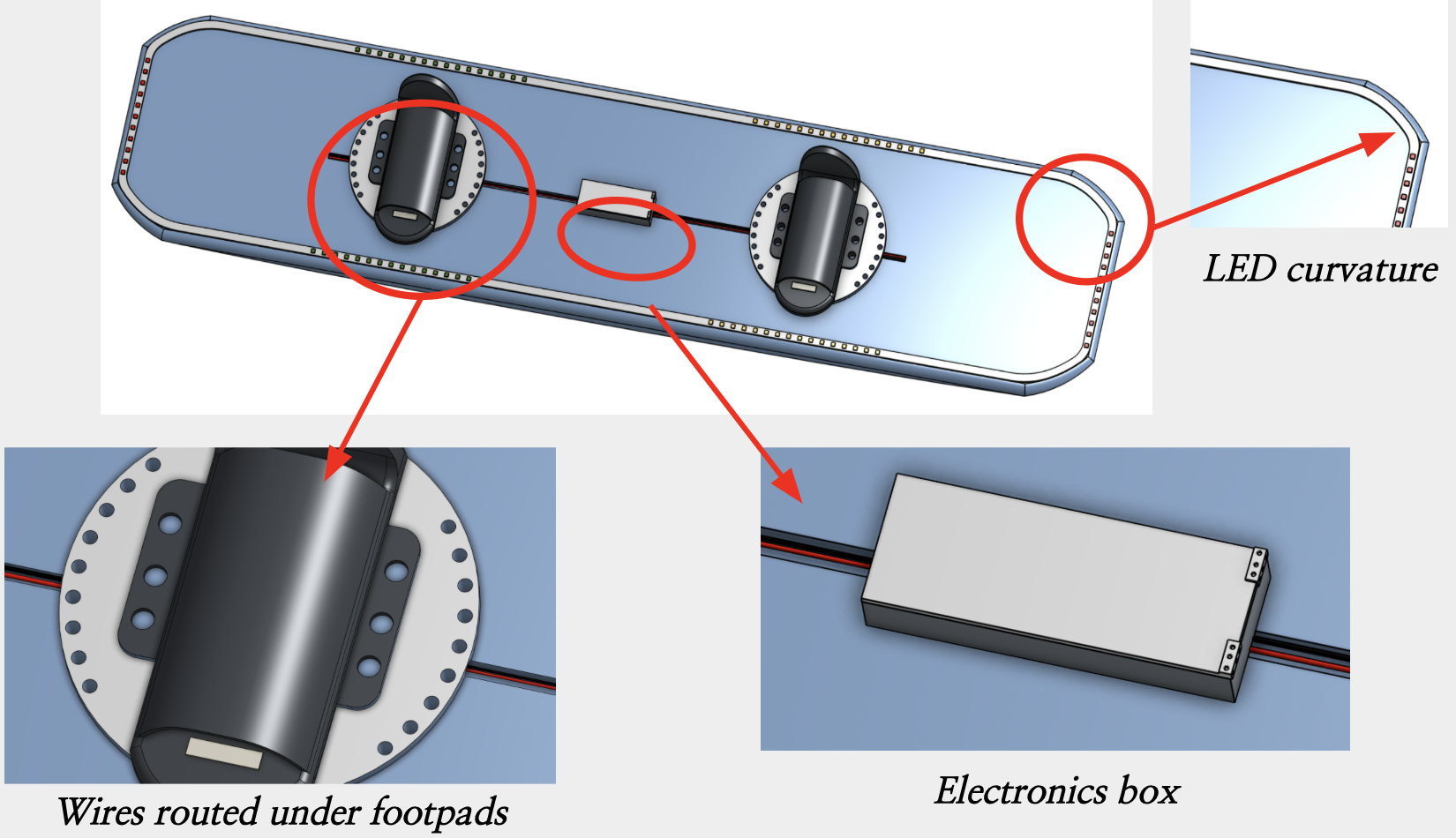

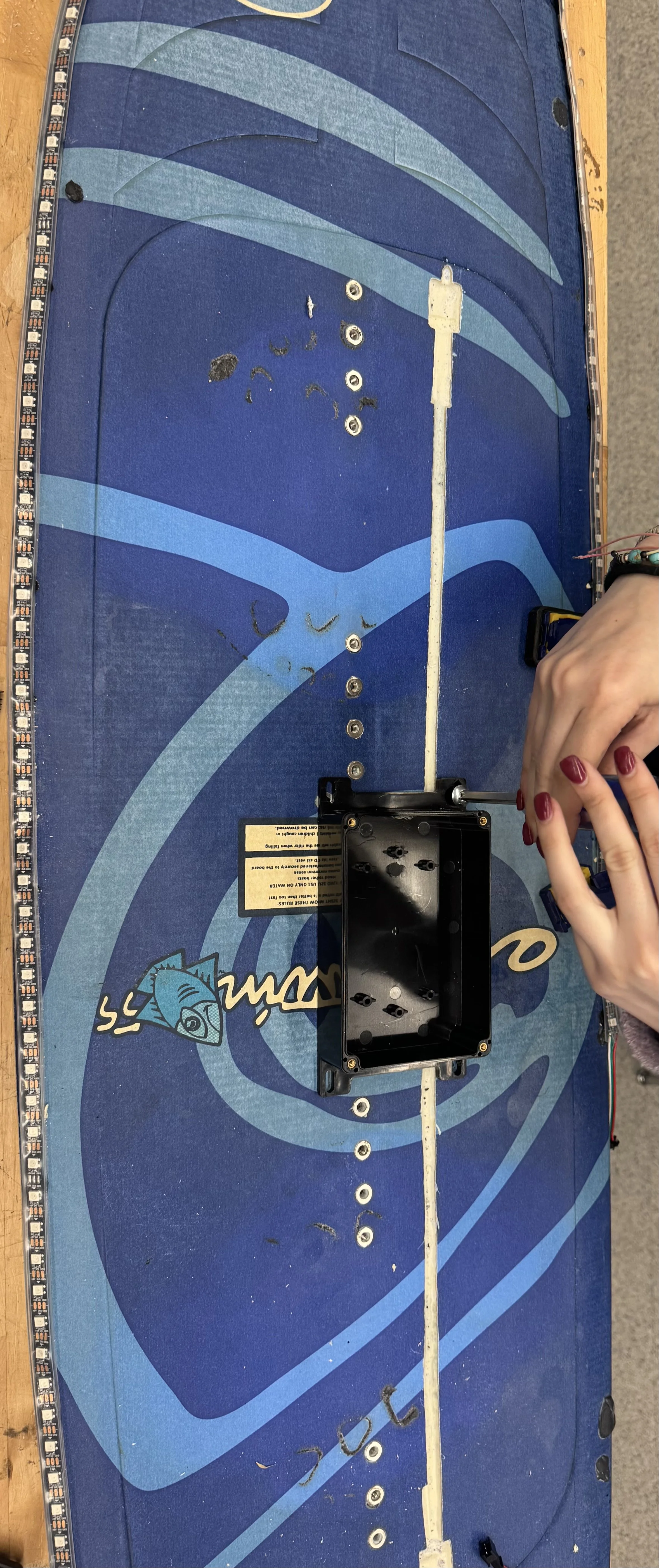

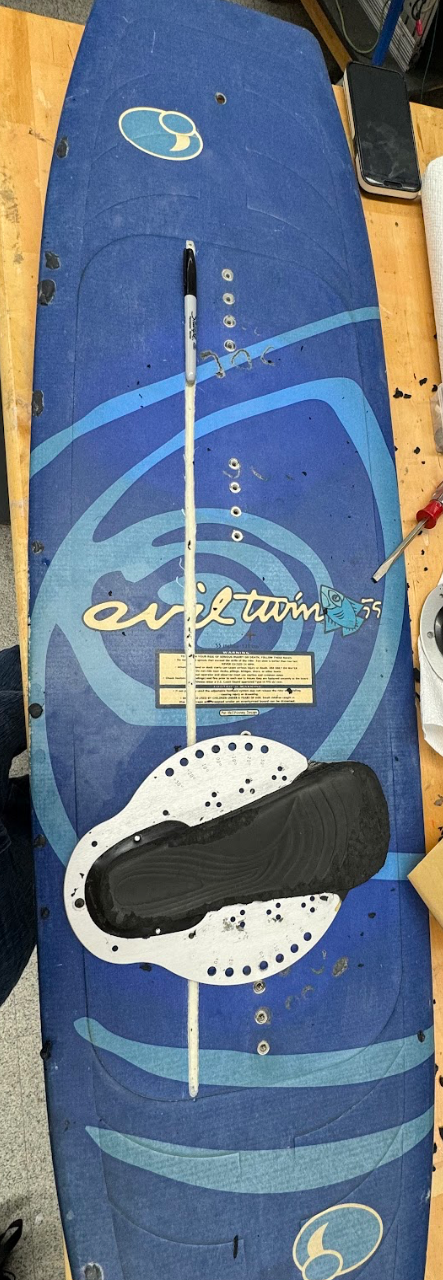

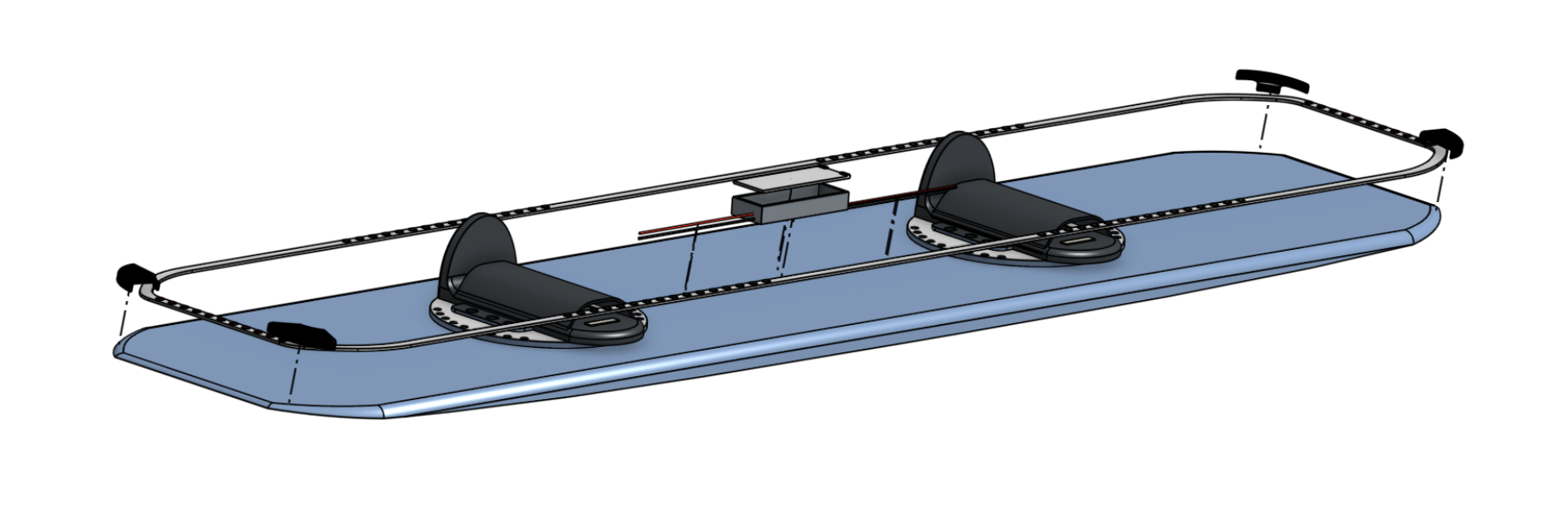

After selecting electronics, a CAD model of the wakeboard was created (and continuously updated) to maintain the final design goal. As shown to the right, the design features LED curvature along the edge of the board, the waterproof electronics box, and wire routing underneath the footpads.

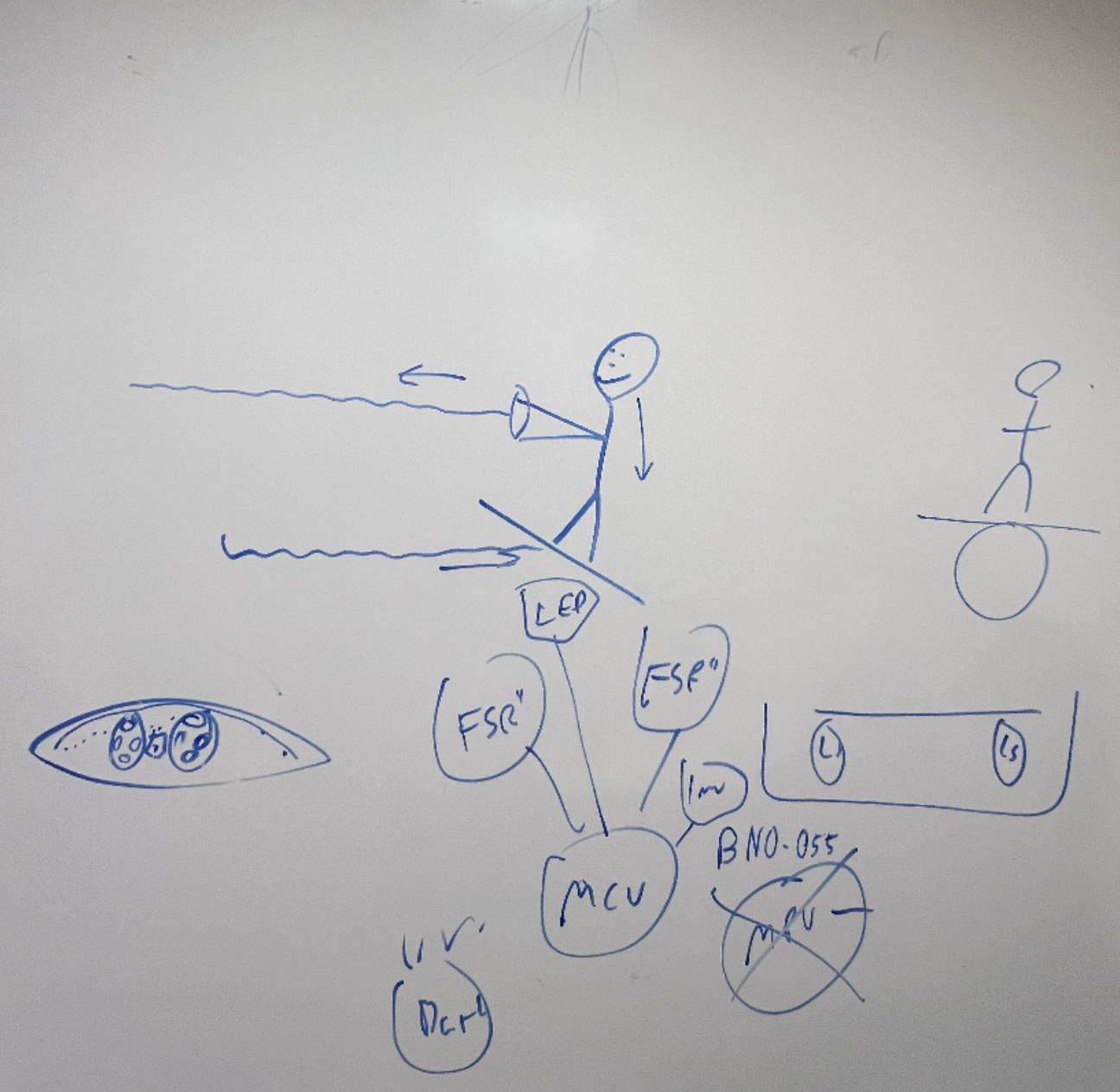

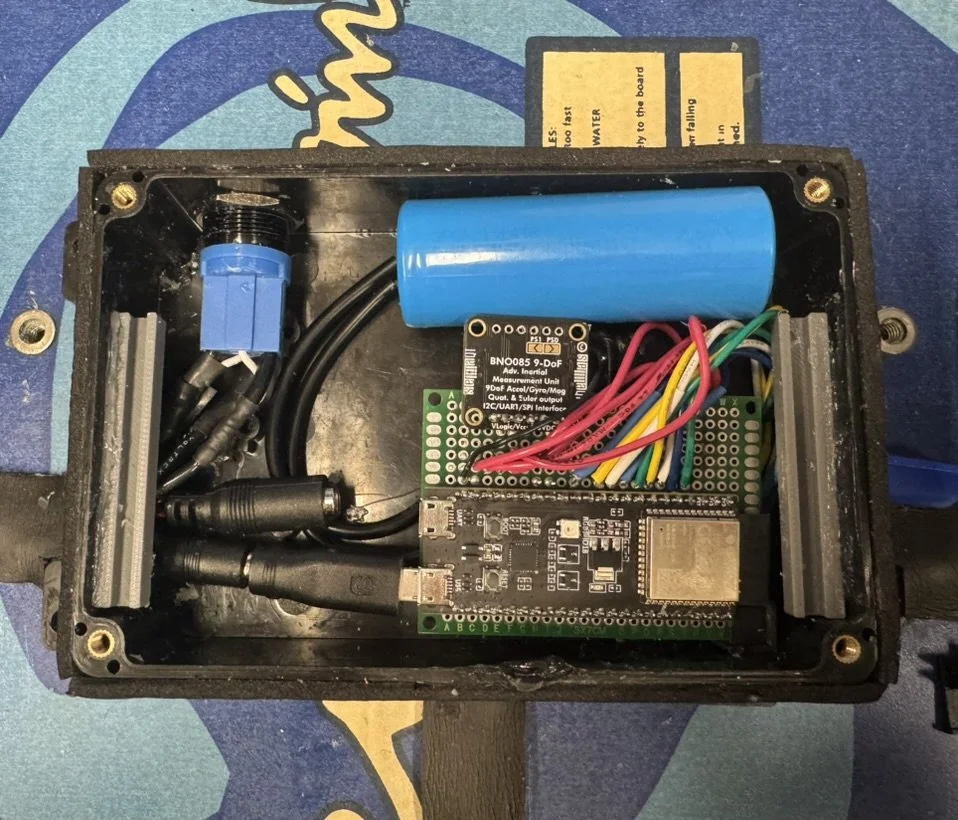

The circuit uses two MF18-N-0A8-A01 wearables, one per foot, a BNO-055 IMU, and a light strip. Four out of eight sensors are used per foot, and these are connected to the circuit using an FPC-10P connector. On a protoboard, the sensor connection from the FPC is connected in series to the analog pin of the microconroller and a 100K resistor, which is grounded. The IMU is an on-board connection and is easily embedded on the PCB.

To keep the device functional, a rechargeable 5V battery pack is used. It is used in tandem with a waterproof button to turn the device on/off without exposing the electronics box to the environment. The battery is removable, while all other electronics are set in place using 3D printed brackets.

The electronics box is secured to the board using threaded fasteners, which allow it to be taken off should maintenance be required.

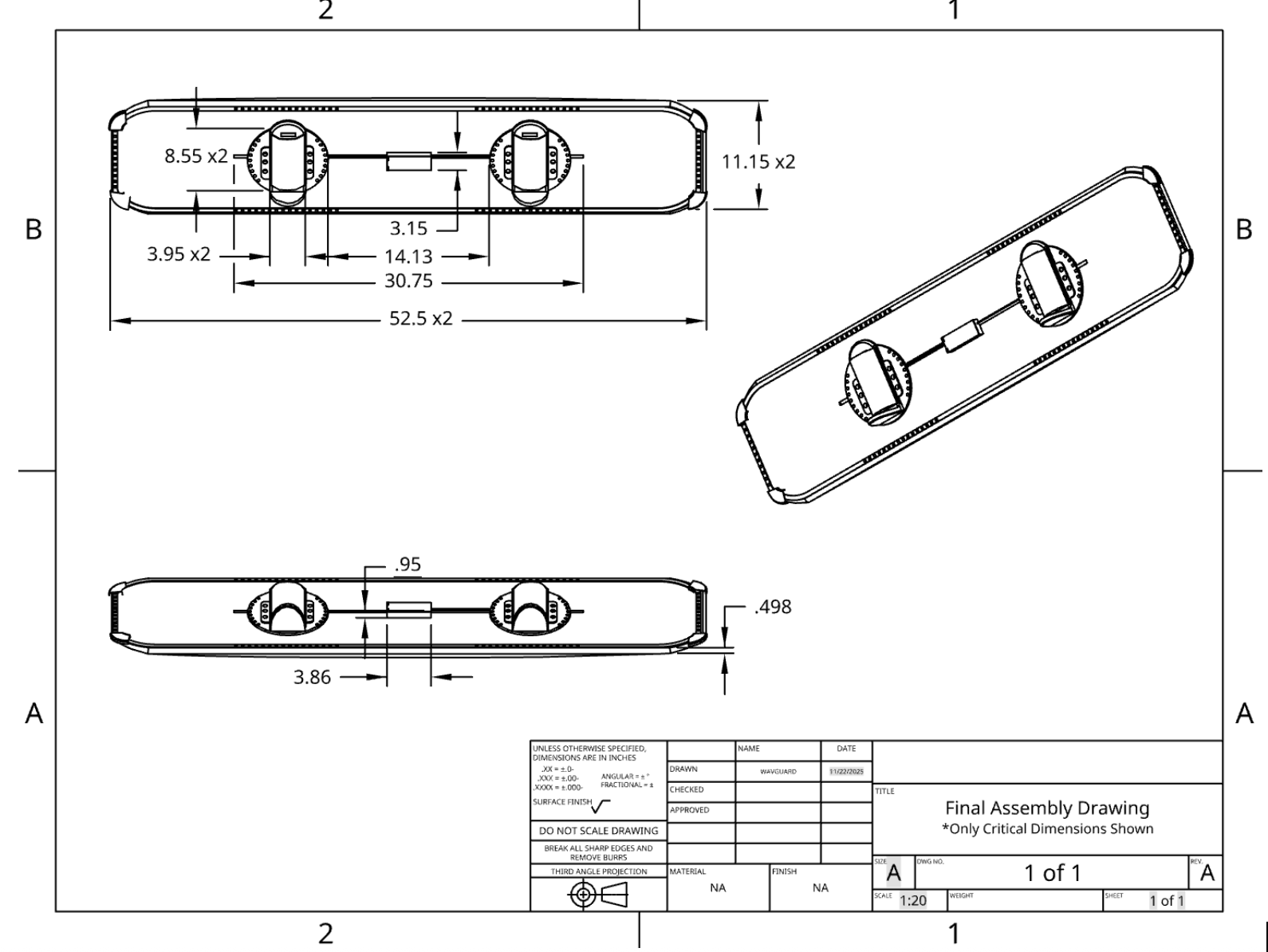

Final CAD model drawing with critical dimensions shown

Design Process

Creating the product was split into two parts: first, integrating sensors and LEDs into a wakeboard to measure disturbance in equilibrium (a simplified system); next, modeling the wakeboarding system, testing on water, and iterating code accordingly.

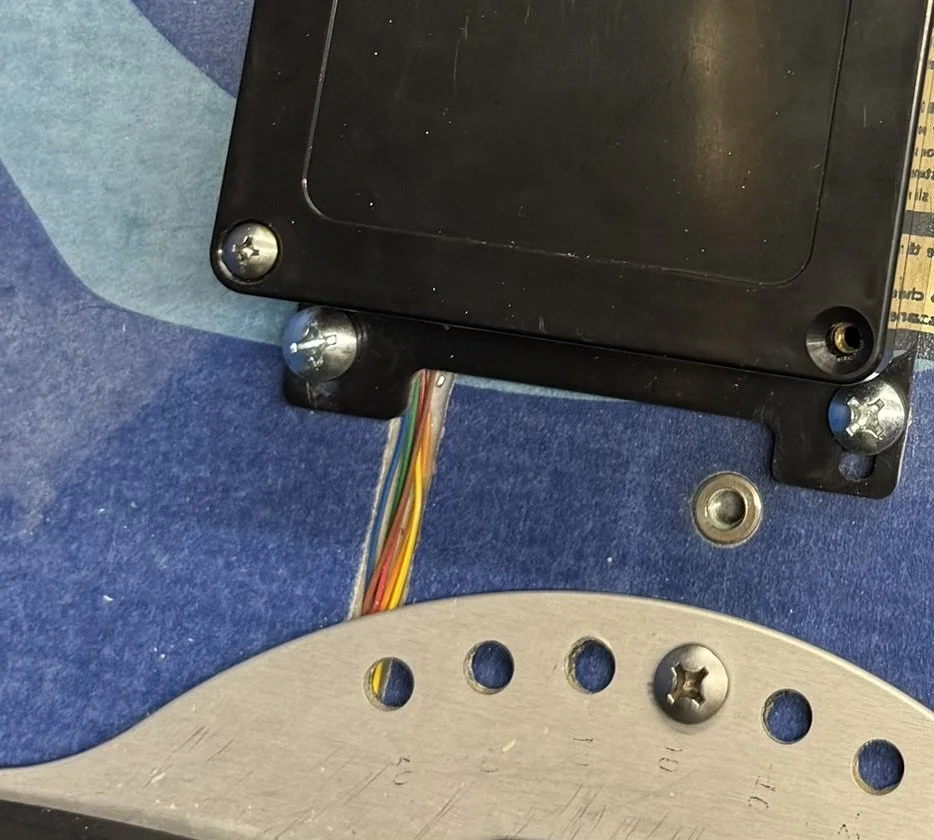

These force-sensitive resistors used are designed for foot pressure sensing. They are embedded into the bottom of the foot brace using a neoprene sheet and waterproofing sealant. Due to their unique geometry and the sensitivity of the thin wires, we used a Dremel and router to route connecting wires under the foot brace, leaving pressure sensor wires undisturbed.

Routed path for wires and FPC board. This method both secures electronics and eases waterproofing, as silicone will cure inside the cavity, leaving a flat surface.

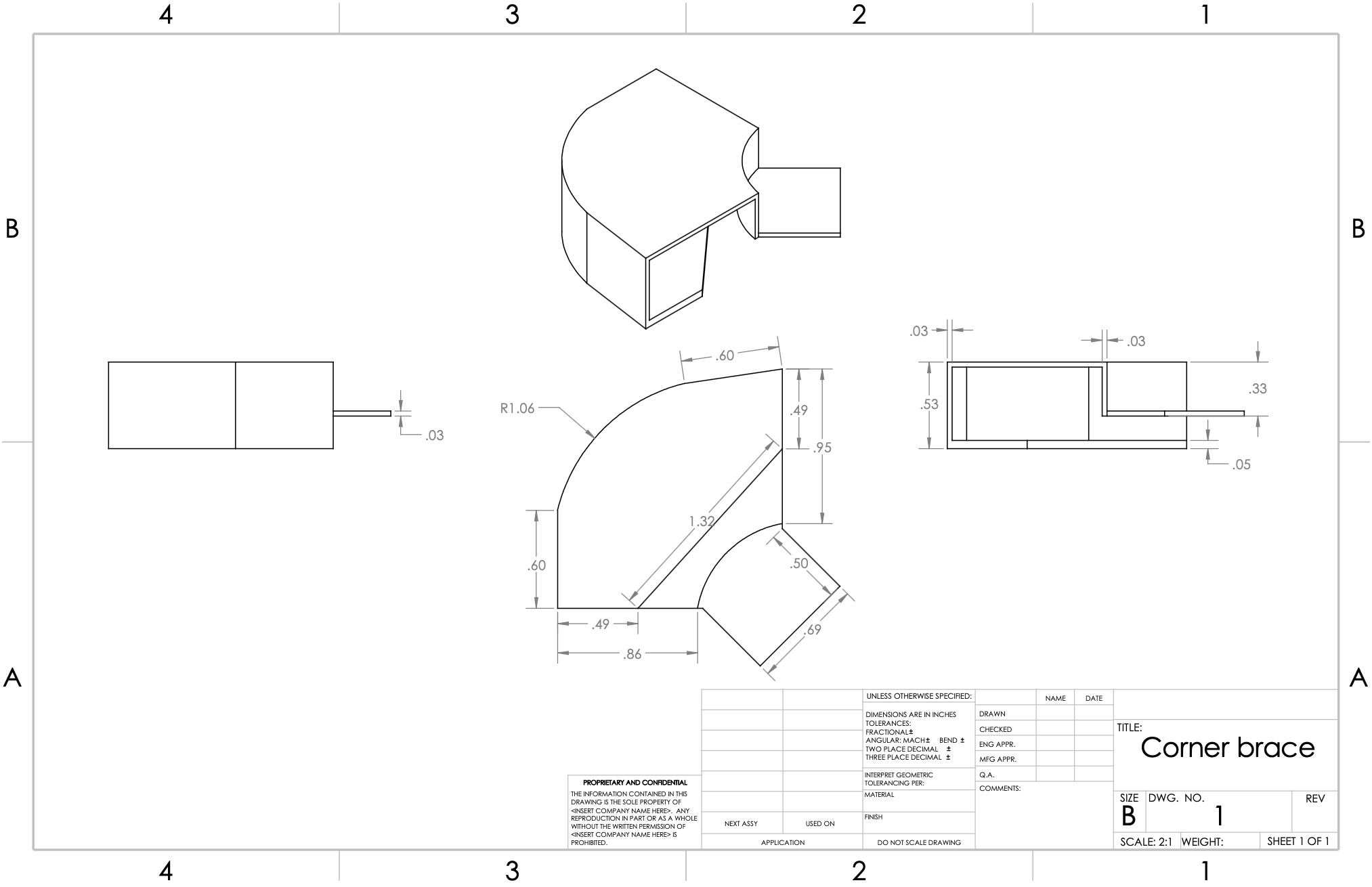

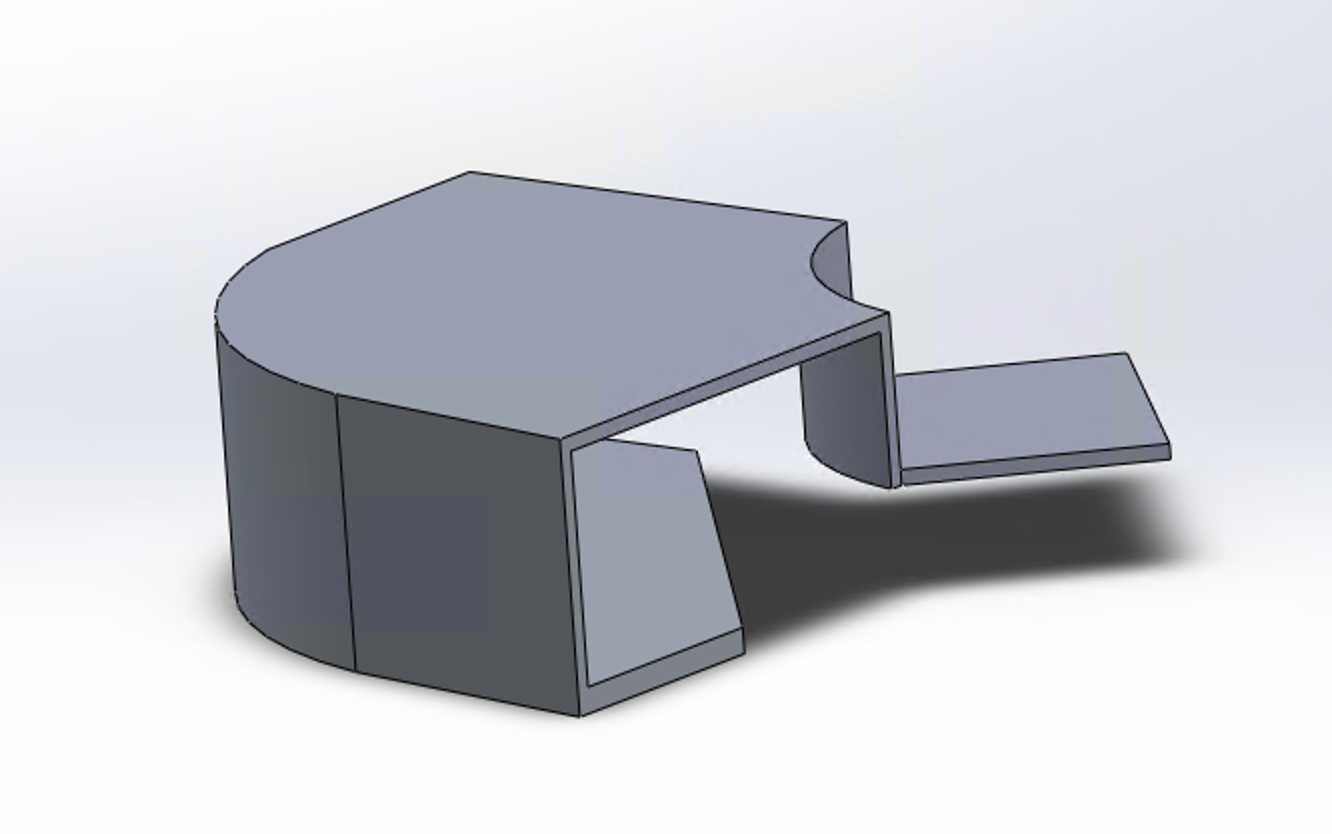

Initially, joints were added to the addressable LEDs to match the curvature of the board. However, this presented difficulties in fully waterproofing the assembly, so lights were instead folded along the corners and custom brackets were designed to fit the edges and secure folds. This way, the silicone seal around LEDs would remain intact while still matching the exact curve of the board. The braces were attached with small screws, and a bottom lip secures them to the board’s underside.

Corner brace Solidworks drawing and 3D model

Electronics

Once the board was fabricated and designed for a simplified system, we began iterating code using more complex dynamic modeling. Forces modeled include tension in the rope, buoyancy, drag, and friction. Finite element analysis provided a starting point to iterate the algorithm, and all subsequent changes were made using results from water testing.

Finally, the board was waterproofed using electronics potting gel, silicone gel, and neoprene sheets. All exposed electronics were covered with several layers of waterproofing in order to avoid damage even when submerged.

Final CAD model exploded view

WaveGuard Smart Wakeboard