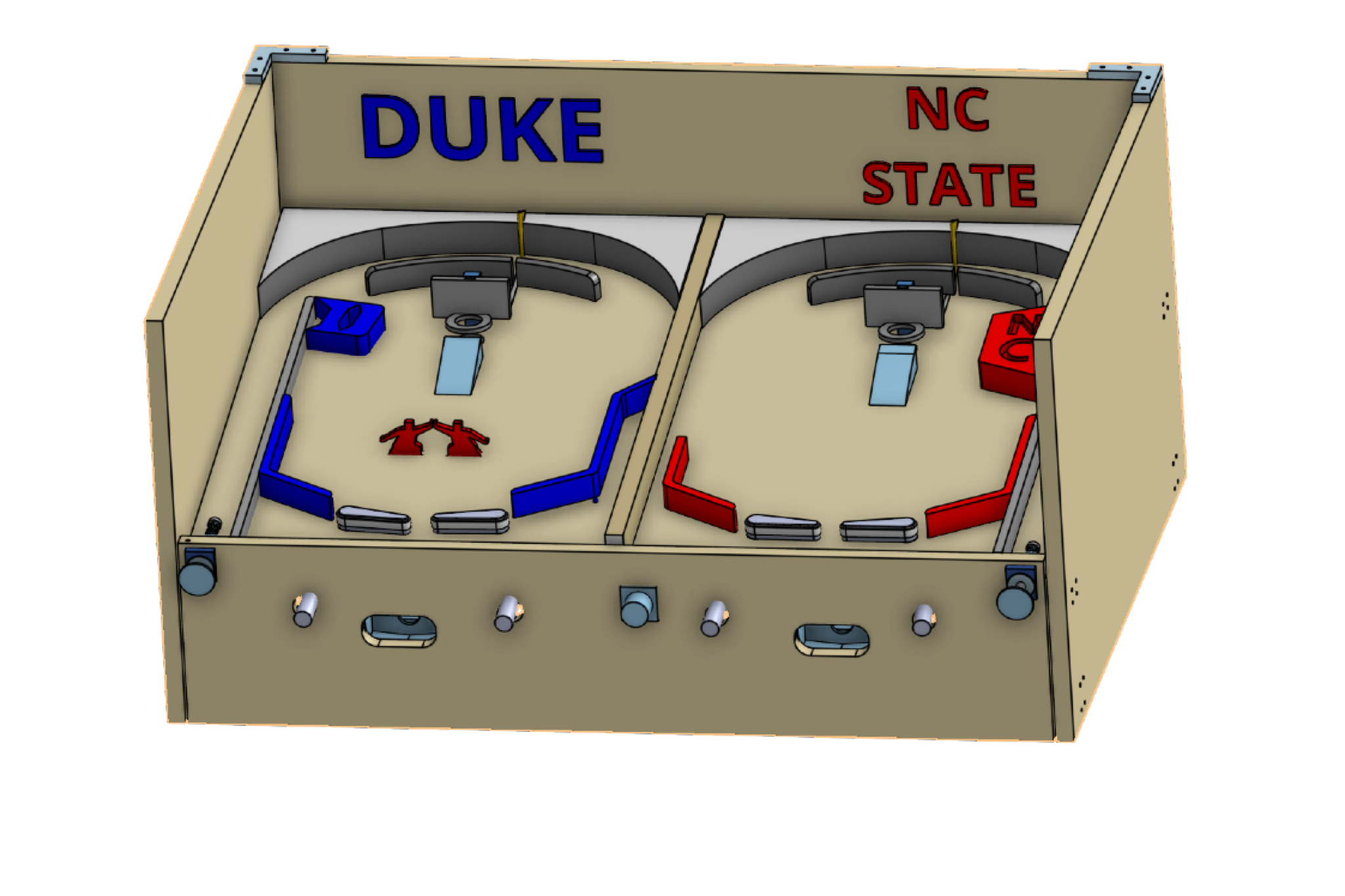

Ball Durham: NC State Fair Pinball Machine

Overview

Over the course of 2 months, I designed and fabricated a purely mechanical, 2 player pinball game for Duke’s annual state fair. The game features a spring-loaded launch mechanism, flippers to control the ball, defenders (controlled by the opposite side’s player) and a return ramp once the ball has successfully been guided up the ramp and into the hoop.

Launcher

Skills

GD&T

Solidworks, CAD Design

Woodworking

Material Selection

Fatigue Testing

Materials

Plywood

PLA

Ball bearings

Compression springs

Components

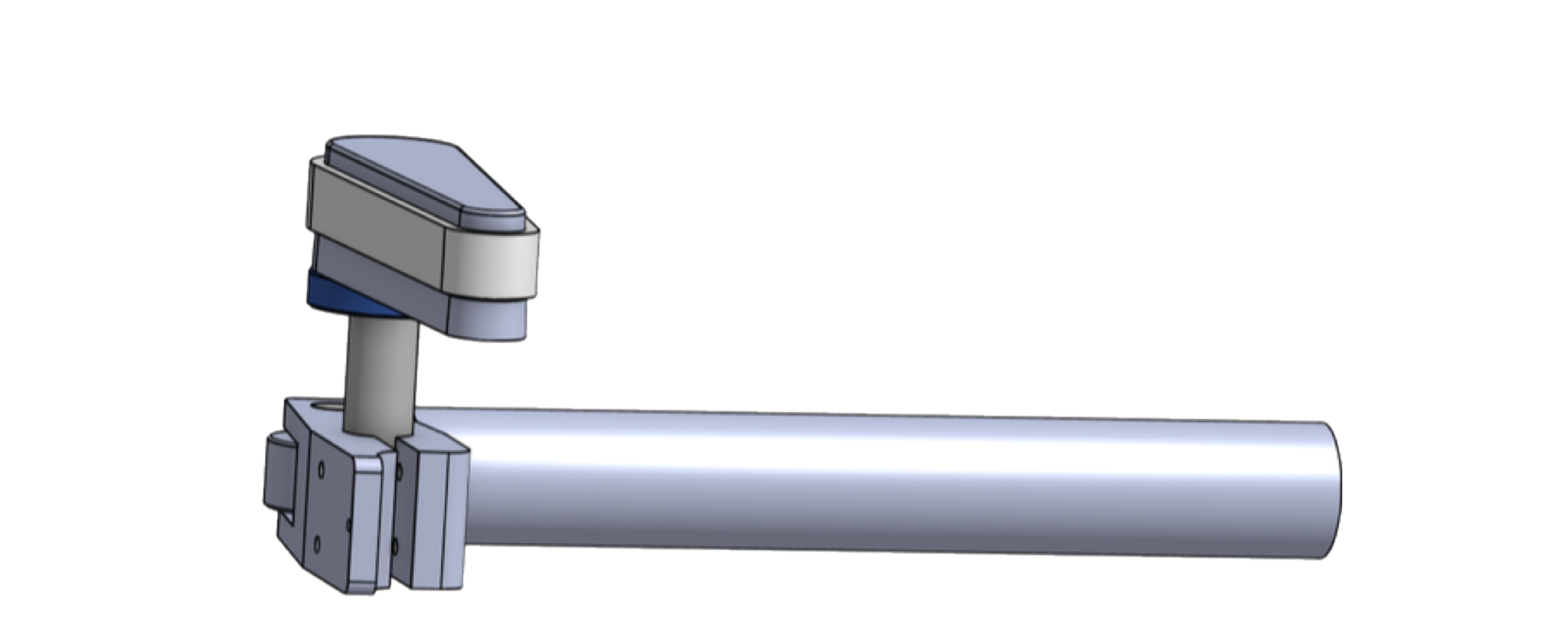

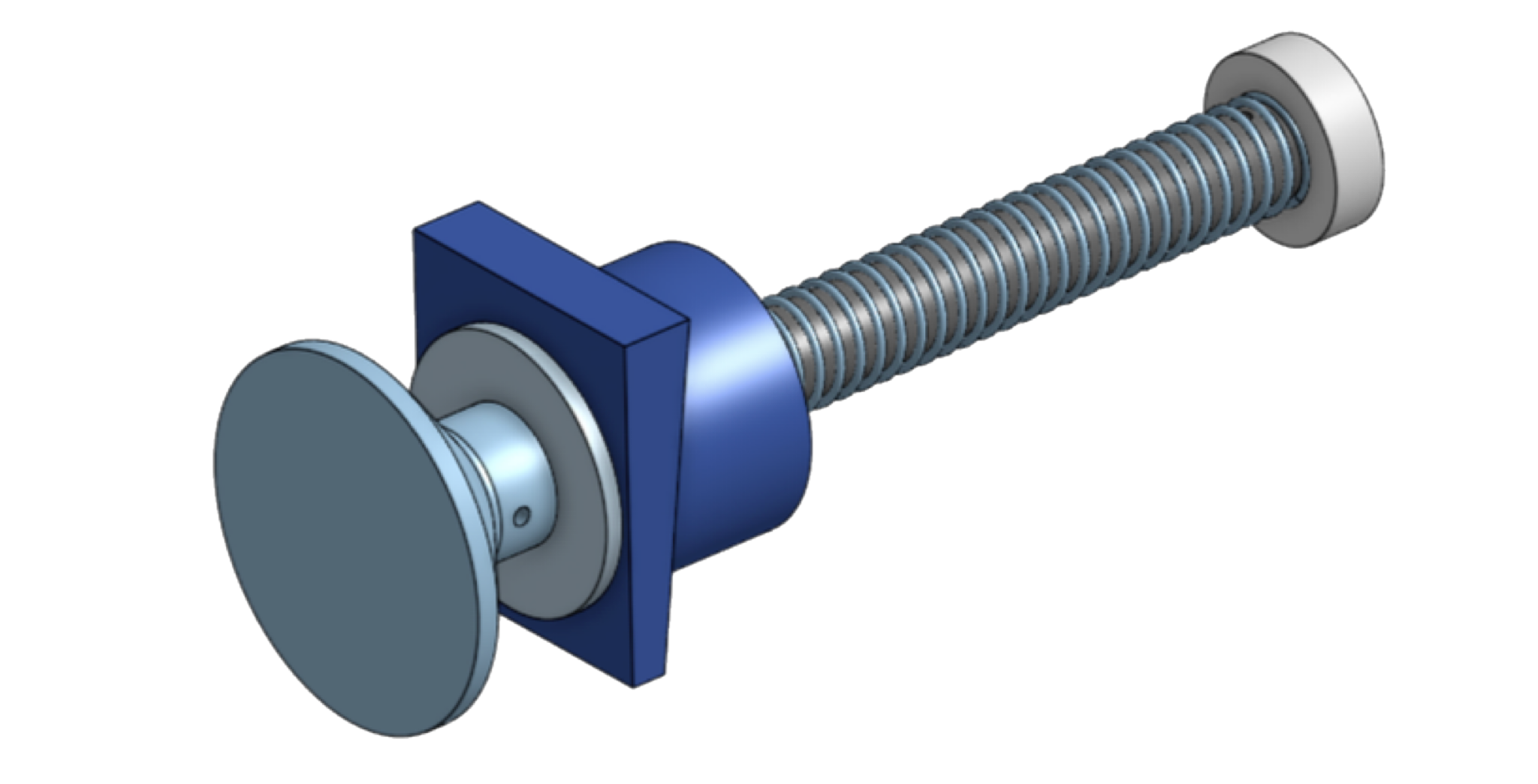

The launcher system consists of a cylindrical guide channel, a compression spring, and a conical handle, damping foam, and force bearing attachment. The spring stores potential energy when compressed by the user and converts it into kinetic energy to accelerate the ball along the launch lane once released. The head, tip, and rod are all fixed using set screws to an aluminum rod with flattened portions the set screw is preloaded to. The only force bearing component here is the spring. The spring was selected based on spring constant, which was calculated to be 2.7 lb/in using ball weight and Hooke’s law. Fatigue and yield calculations using Goodman criteria were completed to ensure the rod diameter is functional.

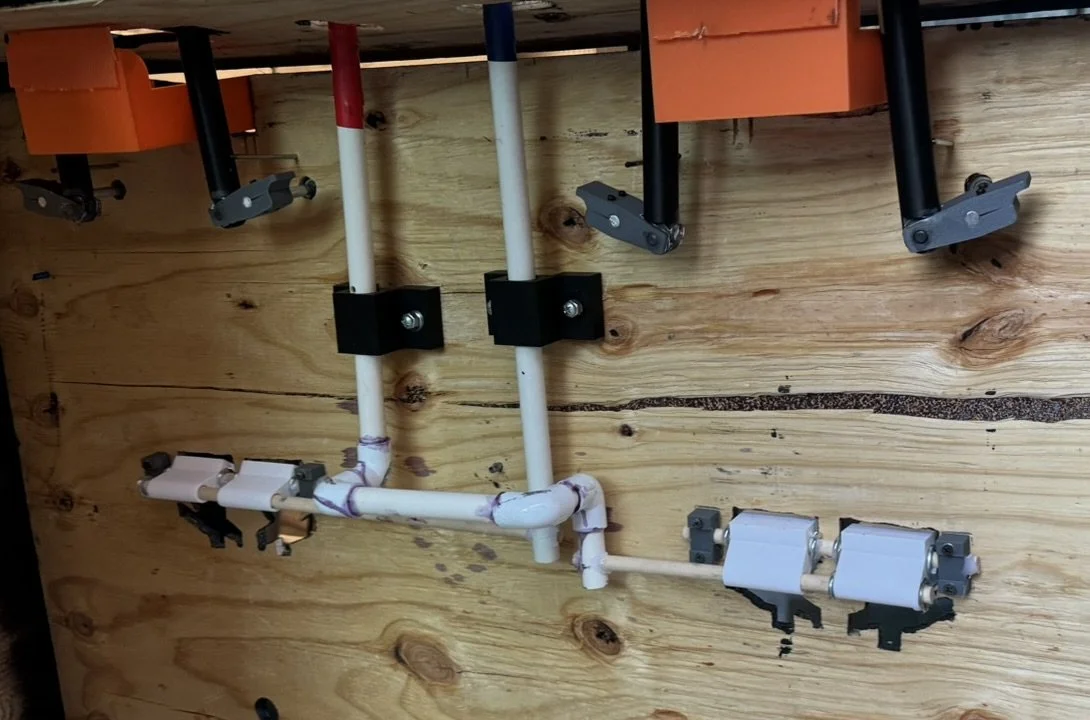

Flipper

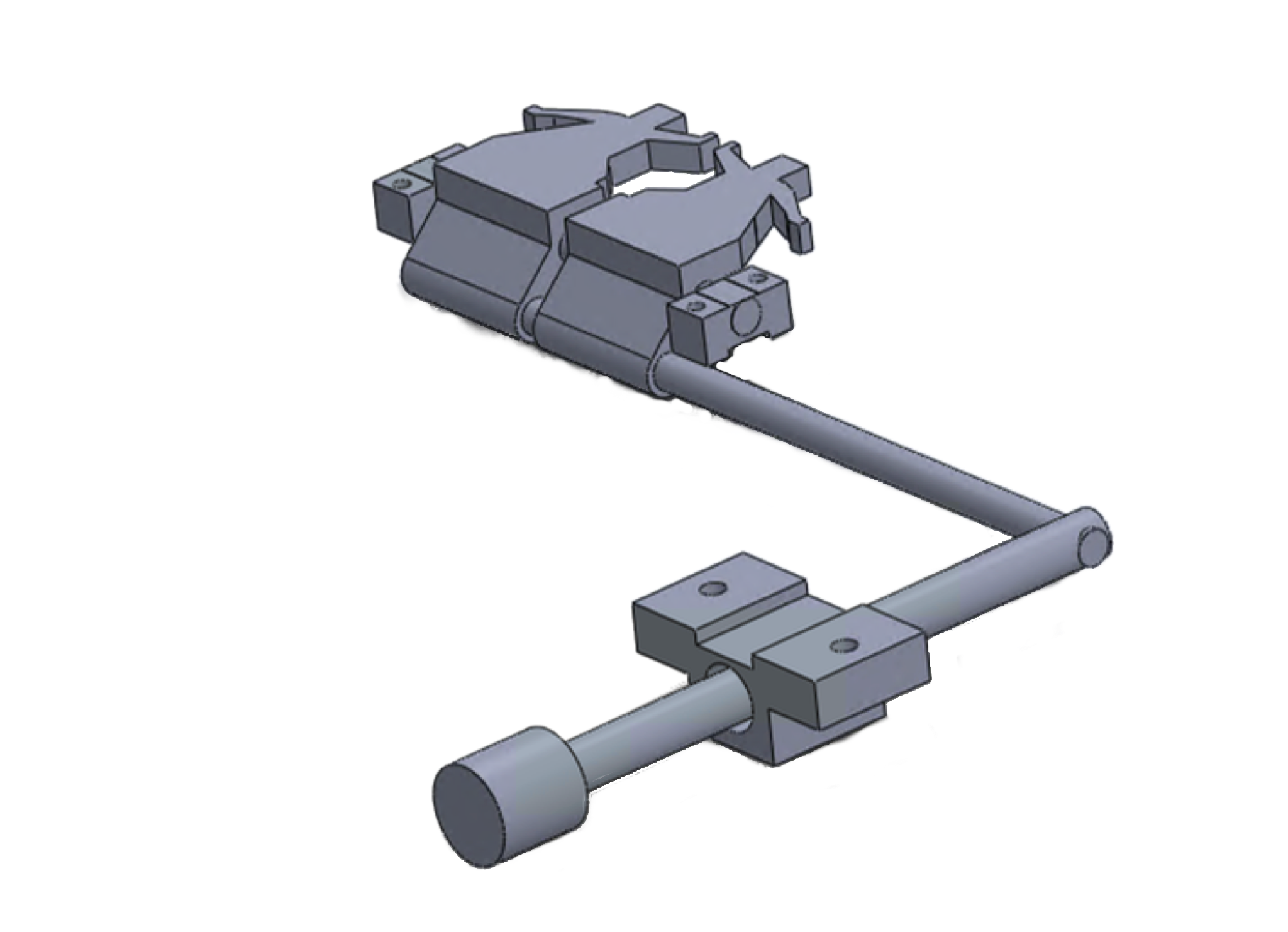

The flipper is mounted to a central steel rod that acts as the rotational axis (parallel to the walls of the board). This rod passes through the pinball board and is supported by a press-fit ball bearing. The flipper is 3D printed and wrapped with a thin rubber sleeve so that the ball makes consistent contact with the paddle. Under of the board, the same rod connects to a 3D-printed lever arm. The free end of the lever is connected to the user’s handle by a steel dowel pin, which allows slight movements as the handle slides while still constraining the lever to rotate with the rod. As the user pushes or pulls the handle, the dowel pin forces the lever to rotate, and therefore the flipper rotates by the same angle. To reset the flippers, a return spring is attached beneath the board, where one end is fixed to the wooden frame, the other to the lever.

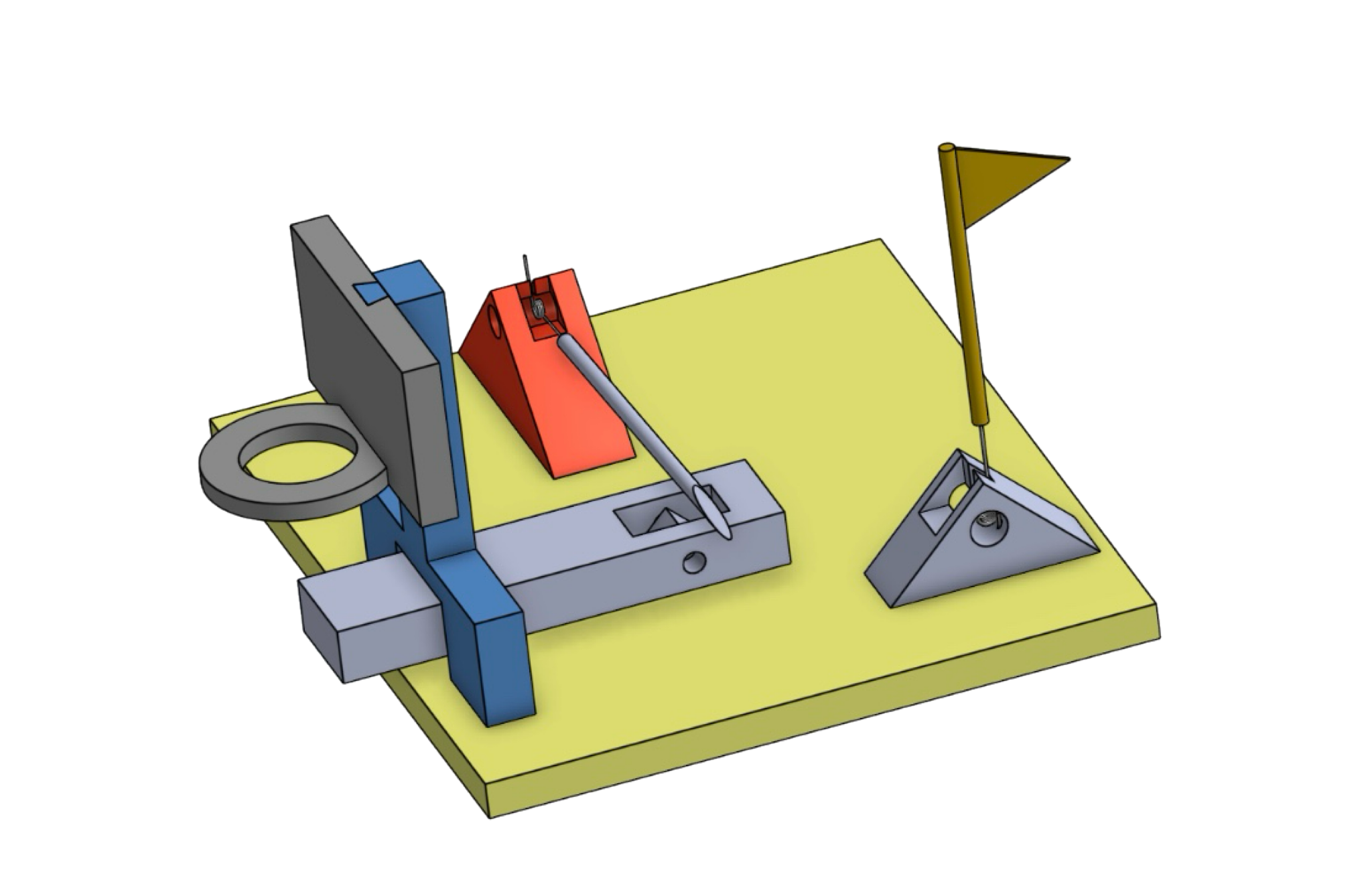

Hoop

The hoop is designed as a target for the players to hit the ball into, and upon the ball falling into the hoop, it will hit a lever that will trigger a mechanism using two torsional springs to release a flag, indicating victory. In order to avoid complex assumptions and calculations, the lever will be weighted such that the mechanism triggers properly. Unfortunately during final integration there was not enough time to integrate all of the mechanisms, so the decision was made to remove the flag functionality and simply install the hoop and mount components without the added mechanical complications of the flag pop-up system.

Final Design and Functionality

Defenders

In order to add a competitive and interactive aspect to the game, a defender mechanism was designed for both sides. The mechanism consists of two mirrored bodies with flaps (positioned 135 degrees from the bodies), two wooden dowels (one of which is fixed to the board via 3D printed pins), a button, a PVC lever, and a bracket that guides the lever along the plane of the board. The mechanism was integrated using the jigsaw to cut out the shape of the bodies from the board surface. When the button is pushed, the defenders rotate until they are stopped (by the cut in the board) in an upright position. While iterating, a .015” tolerance was added to the holes in the defenders, which allowed the wooden dowels to rotate relatively freely. Additionally, in the final assembly, washers were added to constrain the defenders horizontally. Due to the weight of the defender bodies, when the button is released, they fall back into ”off” position, or flush with the board’s surface.

Challenges and iterations

While integrating each component into the project, several failure points were discovered. Firstly, the ball was not funneling smoothly into the launch mechanism, so a funnel was rapidly designed using CAD and 3D printed.

Additionally, when integrating the flippers, we realized they would need a “stopping point”— their motion was not constrained along the x-axis. To combat this, a long nail was added to constrain the flippers in the x-direction, making their use much easier for players.

Finally, because the defenders are controlled by the opposite team, a mechanism was needed to avoid contact between both sides’ levers. A PVC elbowed system was therefore added and cemented (see bottom of board!).